Fabrics of Textile Materials (6): Basic organization and properties of knitted fabrics

Many people have misunderstandings or do not understand “Textile Materials: Fabrics (6): Basic Organization and Performance of Knitted Fabrics“. Next, let the editor take you along and share it with your friends. , explore knowledge about “Textile Materials Fabrics (6): Basic Organization and Properties of Knitted Fabrics“…

The structure of knitted fabrics is a collection of yarns that are bent into loops, stacked longitudinally, and connected laterally. The basic structural unit of knitted fabrics is coils. The coils are connected transversely to the structural features of weft knitted fabrics, and the coils are connected longitudinally to the structural features of warp knitted fabrics.

1. Basic organization of weft knitted fabrics

The basic structures of weft knitted fabrics include weft plain weave, rib weave, double reverse weave and double rib weave.

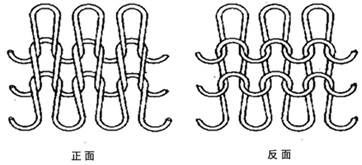

1. Weft weave

The weft weave, also known as the plain weave, is a simple and commonly used single-sided weave in knitted fabrics. The weft weave is composed of continuous unit coils strung together. Each coil on the same side of the fabric is exactly the same in size, shape, and structure.

The front side of the weft knitted fabric is even and flat with good luster, while the reverse side is rough and has a darker finish. The longitudinal breaking strength of the fabric is greater than that of the transverse direction, the texture is thin, and the breathability is good. In the free state, the weft plain knitted fabric has serious curling phenomenon. The longitudinal edges are reversely rolled along the longitudinal direction of the coil, and the transverse edges are forwardly rolled along the horizontal direction of the coil. In addition, flat weft knitted fabrics are easy to fall apart.

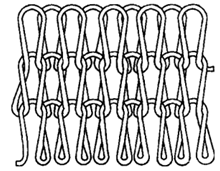

2. Ribbed tissue

The rib structure is the basic structure of double-sided weft knitted fabrics. It is a structure formed by the front wale and the back wale, which are arranged in a certain structure. Each course of the rib weave is knitted by a spinning yarn, which knits both front and back coils. The front and back of the fabric are the same, both showing the appearance of front loops.

Rib tissue is an elastic tissue. When the fabric is stretched transversely, it has greater ductility and elasticity, and the higher the density, the better the elasticity. The rib weave is a double-sided structure, and the fabric is not easy to curl or fall apart. In addition, because the reverse coil of the rib tissue is hidden behind the front coil, the thickness of the rib tissue is thicker and has better thermal insulation performance.

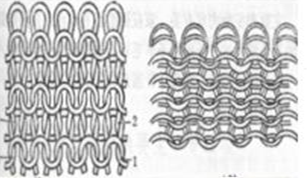

3. Double negative organization

It is composed of front coil rows and back coil rows alternately arranged. The appearance of the reverse side of the weft is given to both sides of the fabric. The double-backed weave shortens the fabric longitudinally due to the inclination of the cylindrical surface, increasing the longitudinal density and thickness of the fabric. The fabric has greater extensibility and elasticity in the longitudinal direction, but it is easy to fall apart along the (or reverse) knitting direction. The double-sided weave fabric feels thick and has good warmth retention.

4.Double rib structure

Double rib weave, also known as cotton wool weave, is made up of two rib weaves that are cross-laminated. The wales of coils of one rib weave are arranged between the wales of another rib weave, and the reverse sides of the coils are covered with each other. Therefore, both the front and back sides of the double rib weave fabric have the shape of the front loops of the weft-knitted plain knitted fabric, showing longitudinal stripes and good finish. The ductility and elasticity of the double rib structure are smaller than that of the rib structure, and the coil detachment is smaller.

2. Basic organization of warp knitted fabric

The basic structures of warp knitted fabrics include warp plain weave, warp satin weave and braided chain weave.

1. Keping Organization

In the warp weave, the loops formed by the same spinning yarn are alternately arranged in two adjacent wale loops. Both the front and back sides of the fabric have diamond-shaped meshes. Because the coils are tilted, the fabric has certain ductility both vertically and horizontally. Its biggest disadvantage is that it easily comes apart in the opposite direction of knitting. When a loop breaks, the fabric easily separates into two pieces along the longitudinal direction.

2. Warp satin structure

Each warp yarn in the weave first moves several stitches in one direction in an orderly manner, and then sequentially moves several stitches while returning to the original position, and so on. The coil shape of warp satin weave is close to that of weft weave, so its curling properties and other properties are similar to weft weave. When a certain yarn in the fabric breaks, there will also be separation in the opposite weaving direction, but there will be no separation in the longitudinal direction of the fabric.

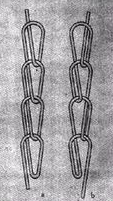

3. Chain organization

Each warp yarn is always looped around the same needle cushion yarn to form a continuous loop.�, divided into two categories: open braided chain and closed braided chain. The braided chain has a tight organizational structure, small longitudinal extension, and is not easy to curl. Generally, it is laminated with other tissues to form knitted fabrics, which can limit the longitudinal extensibility of the fabric and improve dimensional stability.

3. Performance of knitted fabrics

1. Scalability

Stretchability is an obvious feature of knitted fabrics, and it is also the obvious difference between knitted fabrics and woven fabrics. Knitted fabrics have greater extensibility and elasticity, and can expand and contract on their own with the activities of the human body, making them more close-fitting and comfortable to wear, and are suitable for underwear and tights.

2.Softness

The coil structure of the knitted fabric makes the yarn bend and occupy more thickness space, and the holding point has relatively little effect. When external force is applied, the coil is easy to deform. In addition, the twist configuration of the knitted yarn is small, so Knitted fabric is soft to the touch.

3. Porosity

The coil structure of knitted fabrics makes the fabrics highly bulky and contains more voids, which is a typical porous structure, so the fabrics have better air permeability and moisture absorption and perspiration. The large voids and relatively large apparent thickness are conducive to retaining more still air, which can improve the warmth retention of work clothes.

4. Anti-wrinkle

When knitted fabrics are bent and compressed by external forces, since the coils can bend, straighten and deform, and the spinning yarn contact points bear the force, rather than the elongation of the fibers, there is little plastic deformation. When the external force disappears, the spinning yarn can quickly recover under the action of its own deformation energy.

5. Shape retention and arching properties

Knitted fabrics have greater stretchability and are easily deformed under the action of external forces, so the dimensional stability of the fabrics is poor. However, the elastic deformation of knitted fabrics is large, so it has excellent shape retention under small deformation. Repeated exertion will cause the fabric to deform and arch, but it is much better than woven fabrics.

6. Dispersion

When the loops of a knitted fabric break or lose the connection between them, the loops will come out of the loops in sequence under the action of transverse external force. This phenomenon of fabric disintegration is called disintegration.

7. Formability

Formability is the unique one-time molding performance of knitted fabrics.

8. Curling properties

When knitted fabrics are in a relaxed state, the phenomenon of wrapping around the edges is called hemming. The hemming directions of knitted fabrics are different in the transverse and longitudinal directions. The edge of the wale of loops of the fabric is bent toward the reverse side of the fabric; while the edge of the rows of loops is curled toward the front of the fabric.

9. Coil skew

When the knitted fabric is in a free state, the loops tend to tilt longitudinally.

10. Raising and snagging

The structure of knitted fabrics is loose, and the twist of the yarn used is low. The fibers are easy to pull out and slip out of the yarn to cause fluffing and pilling, or are hooked by hard objects to form silk loops, which are called fluffing and snagging respectively.

Textile Materials – Fabrics (6): Basic Organization and Properties of Knitted Fabrics

AAAERT5Y4375JTY

Through the above review of “Textile Materials – Fabrics (6): Basic Organization and Properties of Knitted Fabrics “, what is your understanding and thoughts about “Textile Materials – Fabrics (6): Basic Organization and Performance of Knitted Fabrics“, or are you interested in purchasing fabrics >, you are welcome to post your comments below the website!

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights and interests, please contact us and we will change or delete it as soon as possible.

AA