Comparison of carding efficiency and effect of machine-picked cotton and hand-picked cotton

Many people have misunderstandings or understanding of “Comparison of carding efficiency and effects of machine-picked cotton and hand-picked cotton“. Next, let the editor lead you to share it with your friends and explore more about it. Knowledge of “Comparison of carding efficiency and effects of machine-picked cotton and hand-picked cotton“…

Cotton quality, picking methods and finishing methods will affect the carding effect and carding efficiency of the blowing-carding, carding, and combing processes. Fine-staple cotton and long-staple cotton produced in different origins and climate environments have different fiber properties. , its combing efficiency and combing effect are also obviously different. But the key to the final difference is harmful fibers and harmful defects. This is because the carding effect and carding efficiency of the blowing-carding, carding, and combing processes are evaluated through the removal of harmful defects and harmful fibers. Generally speaking, harmful defects and fibers with strong dispersion in cotton fibers are easily removed during the carding process. The quality of cotton batting and slivers in the cotton layer is better, and the carding effect and carding efficiency are also good; conversely, if cotton fibers appear If a large number of harmful fibers and harmful defects are entangled or mixed in the fibers, the carding effect will be reduced.

After Xinjiang’s machine-picked cotton reaches a certain output, due to the obvious differences between its performance and the quality properties of foreign machine-picked cotton and Xinjiang’s hand-picked cotton, it is necessary to strengthen the carding effect and carding efficiency of Xinjiang’s machine-picked cotton and hand-picked cotton. Comparative analysis, on the one hand, can find the difference in carding quality between the two, on the other hand, the process settings, equipment management and equipment maintenance of Xinjiang machine-picked cotton can be analyzed to stabilize the carding effect and the quality of cotton layer and sliver, and promote The improvement and improvement of Xinjiang’s machine-picked cotton-related technologies and standards will realize the standardization and standardization of Xinjiang’s machine-picked cotton process from seed to ginning.

Reasonable grabbing improves pre-combing effect

As the quality grade of cotton decreases, whether it is hand-picked cotton or machine-picked cotton, its pre-carding effect, impurity removal and short fiber removal rate will become worse. The pre-carding effect and pre-carding efficiency of the blowroom-carding unit must be determined based on the quality grade of cotton used, the quality requirements of final carded sliver and combed sliver, and the quality requirements of cotton yarn. It does not mean that the higher the pre-carding efficiency, the better the pre-carding effect. good. Under normal circumstances, the pre-carding efficiency of Xinjiang machine-picked cotton of the same grade is higher than that of Xinjiang hand-picked cotton, but the pre-carding effect is poor. Long-term production practice has proved that only after fully analyzing the harmful defects, hazardous fiber types and quantities of Xinjiang machine-picked cotton can the pre-carding efficiency and the pre-carding efficiency and cleaning process of Xinjiang machine-picked cotton of different grades and different qualities be determined. Pre-combing effect.

Adopting the same blowing and carding process and technology, analyzing and comparing the pre-carding effects of machine-picked cotton in Xinjiang and hand-picked cotton in Xinjiang, we can further explore the optimal process and technology of machine-picked cotton in Xinjiang, guide its future development direction, and formulate The control range of pre-carding efficiency and pre-carding effect of Xinjiang machine-picked cotton of different quality grades will be narrowed down to the control range of harmful fibers and harmful defects, and the quality of carded slivers, combed slivers and cotton yarns of Xinjiang machine-picked cotton will be improved. At present, the problem that is difficult to control is the problem of mulched foreign fibers in machine-picked cotton in Xinjiang. Their colors are close to cotton fibers and vary in shape and size. They are fragile during the blowing, carding, catching and opening processes, and will further form more foreign fibers. Fibers are difficult to remove, which affects the pre-carding effect of the blowroom-carding unit and brings trouble to the subsequent carding process. If it can be absolutely cleared using an automatic winding electronic yarn clearer in the blowroom-carding combined cleaning process, or if it can be quickly melted and removed using the microwave principle or thermal effect principle, it will be a major breakthrough in blowroom-carding combined pre-carding technology.

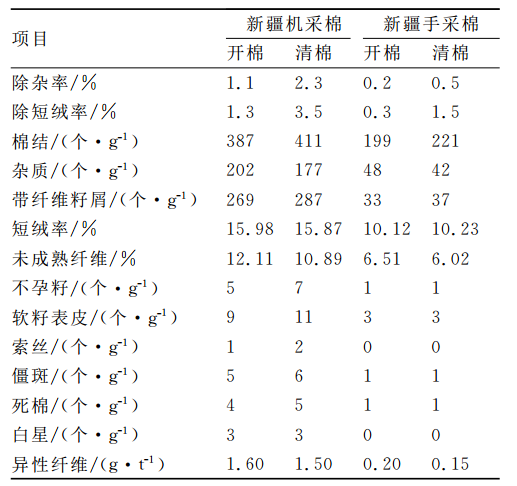

The data in Table 1 shows that from opening to cleaning, the impurity removal rate and short lint removal rate of machine-picked cotton and hand-picked cotton in Xinjiang are increasing, and the former is 4 to 5 times higher than the latter. This is because the content of impurities and short lint in Xinjiang machine-picked cotton is 2 to 6 times higher than that of Xinjiang hand-picked cotton. The test statistics of harmful defects and harmful fibers in the cotton layer during opening and cleaning show that the harmful fibers contained in Xinjiang machine-picked cotton are complex in composition, and the number of harmful defects is large and small, making it difficult to reduce them exponentially. In order to prevent the Xinjiang machine-picked cotton from being shattered and causing more harmful defects and harmful fibers during the ginning process, a reasonable grasping process needs to be adopted, and the cotton layer of the cotton layer with more foreign fibers needs to be harvested and ginning. It takes time to solve and reduce the pre-carding burden of the blowroom and carding unit.

Efficient carding increases carding efficiency

The common carding effect and carding efficiency controls in the carding process are mainly for fine-staple cotton or long-staple cotton of different grades and qualities. The carding effect and carding efficiency control of machine-picked cotton are mainly for Australian cotton, American cotton of different quality grades, and a small amount of Brazilian cotton. The control of carding effect and carding efficiency of Xinjiang machine-picked cotton is still being explored. This is because there are obvious differences in physical quality indicators between different batches of Xinjiang machine-picked cotton of the same grade, making it difficult to control the carding effect of carding through stable carding efficiency. . Therefore, it is necessary to formulate practical and feasible quality control standards for machine-picked cotton in Xinjiang, which can not only stabilize cotton quality but also control carding efficiency and carding effect according to its different quality levels.

CurrentlyThere are no unified standards for the planting, management, picking and finishing of machine-picked cotton in Xinjiang, resulting in its main physical indicators being messy and containing a large number of harmful defects, harmful fibers and harmful foreign fibers. Only a large number of single-mark trial spinning is carried out in the carding process. , adjust process data, use carding equipment and carding technology to cooperate, and strengthen the maintenance and repair of carding equipment to improve and enhance the carding efficiency and carding effect. Developing different carding quality range controls for Xinjiang machine-picked cotton with different characteristics is the key to preventing effective fiber damage caused by excessive carding efficiency during the actual production process, and is also the key to preventing excessive production costs. How to use the characteristics of large carding area and many carding points in the carding process to overcome the difficulty in removing the foreign fibers unique to machine-picked cotton in Xinjiang during the blowing and carding process, especially the mulching foreign fibers, is the key to improving the carding effect and carding efficiency. It is an important link and also the key direction of future technological changes.

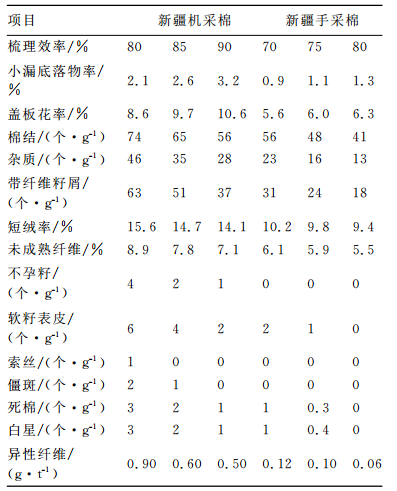

The data in Table 2 shows that with the improvement of carding efficiency in the carding process, the drop rate of machine-picked cotton and hand-picked cotton in Xinjiang increases, and the harmful fibers, harmful defects, and mulching foreign fibers decrease, indicating the carding effect. Stronger, compared with the quality of the cotton layer in the cleaning process, harmful defects are reduced by 10% to 100%, and harmful fibers are reduced by 10% to 50%. While the carding efficiency of the cotton layer of hand-picked cotton in Xinjiang is lower than that of machine-picked cotton in Xinjiang, the physical indicators of carded slivers are better than that of machine-picked cotton in Xinjiang, indicating that harmful defects and harmful fibers in Xinjiang machine-picked cotton have a great impact. Large, the carding, impurity removal, and short lint removal processes of the carding process should be formulated based on its fiber properties, and the carding efficiency can be further increased through efficient carding.

Reduce combing waste and reduce costs

The cylinder density and angle of the combing machine increase, and the tooth density of the top comb increases. On the one hand, it ensures better combing effect while reducing the combing noil rate. On the other hand, the combing efficiency decreases. In this case, the combing effect of the combing process will not be reduced. The backward cotton feeding mode is changed to the current forward cotton feeding mode, which prevents the hooked neps caused by the fiber rubbing between the top comb and the cylinder. The progress of top comb, cylinder tooth density, shape and angle in the combing process has made up for the quality defects of machine-picked cotton in Xinjiang and increased the application scope of its combed cotton yarn; if the carding machine is equipped with a larger number of high-end The tooth-density flat plate and cylinder can also ensure the carding effect of the carding sliver while reducing flat plate flowers, prevent damage to the carding equipment and reduce the service life due to excessive carding efficiency, and can also reduce the film resistance of Xinjiang machine-picked cotton. Opposite sex fibers. All in all, the progress of combing and carding equipment has promoted the progress of blowing and carding equipment, and carding and carding equipment, which can achieve more reasonable carding effects for cotton of different grades and different qualities, and prevent

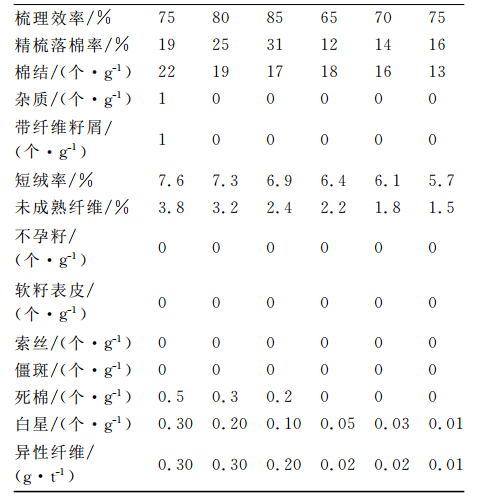

The data in Table 3 shows that the combing machine has a good effect on shorting the cotton layer formed by the carded sliver. On the one hand, it blocks a large number of larger defects and floating fibers from entering the combed sliver. On the other hand, it removes more lint from the combed sliver. Harmful defects and hazardous fibers are discharged into combed noil, especially some defects and fibers that have a great impact on the quality of the cloth surface have become combed noil. However, an excessively high combing noil rate will This will increase the cost of machine-picked cotton production in Xinjiang. Although the mulching foreign fiber has been greatly reduced, its stock in combed sliver is still much higher than that of hand-picked cotton in Xinjiang. In addition, under the condition of high waste rate, there is a big gap between machine-picked cotton and hand-picked cotton in Xinjiang in terms of combed sliver quality, and the carding efficiency of the combing process is also 15% to 20% higher than that of hand-picked cotton in Xinjiang. Only in this way can the combing effects of the two combing strips be closer. Therefore, in order to prevent the excessive carding efficiency of the combing machine from damaging the equipment and carding equipment parts, it is necessary to completely reduce the harmful defects and harmful fibers existing in machine-picked cotton in Xinjiang. Otherwise, not only the production cost will be high, but the quality of the cotton yarn will also be deteriorated. Hard to maneuver.

The opening, impurity removal, short lint removal, pre-carding, and combing processes of blowing and carding, carding, and combing all have certain limitations in removing harmful defects and fibers in cotton, so Xinjiang The quality of machine-picked cotton and hand-picked cotton determines to a certain extent the carding efficiency and effect of the blowing-carding, carding, and combing processes. The development of carding technology and carding equipment has made use of the highly harmful fibers and harmful defects of Xinjiang machine-picked cotton to a certain extent. However, its production cost is high, and the final cotton yarn quality and fabric quality are not ideal. Therefore, improving the quality of machine-picked cotton in Xinjiang and reducing harmful defects and harmful fibers in machine-picked cotton from the source are still the focus of development.

(Author: Xiong Wei, Xinjiang Wopu Agricultural Progress Co., Ltd., Tang Xiaoli, School of Fabric Workwear, Hunan University of Technology)

AAAVBJYTUJGHNH

Through the above description of “Comparison of carding efficiency and effects of machine-picked cotton and hand-picked cotton“, you will know about “Comparison of carding efficiency and effects of machine-picked cotton and hand-picked cotton“, or if you are interested in purchasing fabrics, you are welcome to post your comments below the website!

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AAADisclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site come from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA