Toray launches cutting-edge apparel R&D laboratory TECHNORAMAIII

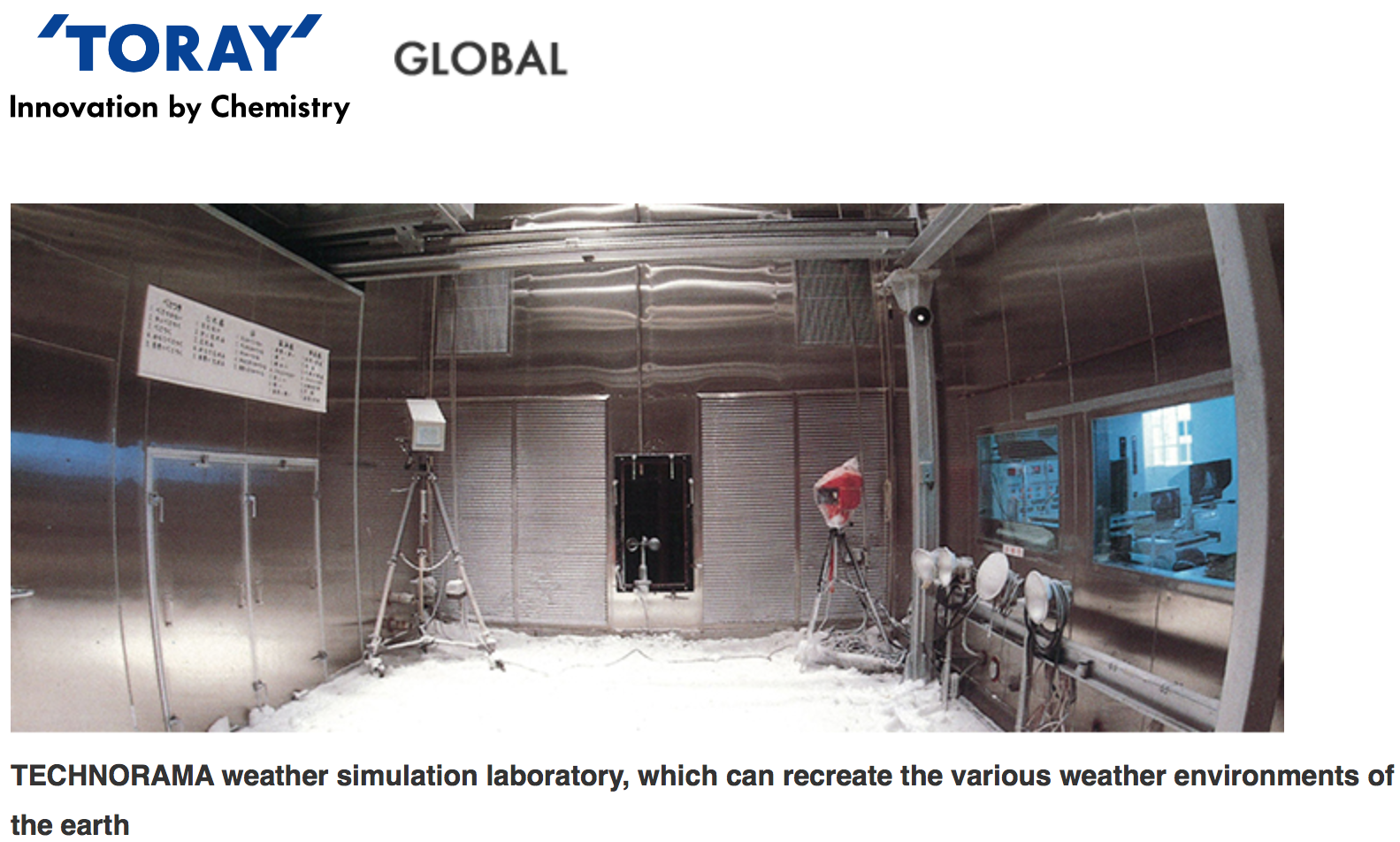

Japanese textile giant Toray recently announced its cutting-edge clothing research and development laboratory: Climate Simulation Laboratory TECHNORAMAGIII.

With an investment of 1 billion yen, this two-story laboratory is located inside Toray’s Seta Factory in Otsu City, Shiga Prefecture, Japan. It has a building space of 940 square meters and three artificial weather rooms that can adjust the temperature at will. Moderate weather conditions, wind speed, rainfall, insolation and other meteorological factors can also simulate extreme weather in the polar circle.

The artificial weather room is also equipped with various equipment such as motion capture equipped with a motion analysis system, 3D body scanning, wireless thermometer, wireless hygrometer, cardiopulmonary ECG and perspiration measurement. In addition, in order to strengthen cooperation with customers and universities, the laboratory also has a textile fabric library equipped with a database of past fabric design drawings and other materials. From fiber physical properties and fabric design-related information to fabric appearance and try-on simulation devices, everything is available.

Toray Executive Director Hisao Sasaki said: “The biggest feature of the third generation TECHNORAMAG III is that it is equipped with the most advanced 3D simulator and other equipment. In addition to textiles, the more important task is to develop the most cutting-edge clothing.”

p>

In 1983, Toray established the first-generation TECHNORAMA laboratory. In 2008, the second-generation TECHNORAMA laboratory was established in Nantong, China, and cooperated with the Japanese fast fashion giant Uniqlo to develop technological fabrics “HEATTECH” and “AIRism”. In October 2017, Toray and Fast Retailing, the parent company of Uniqlo, held a large-scale product expo The Art and Science of Life Wear at Spring Place in Manhattan.

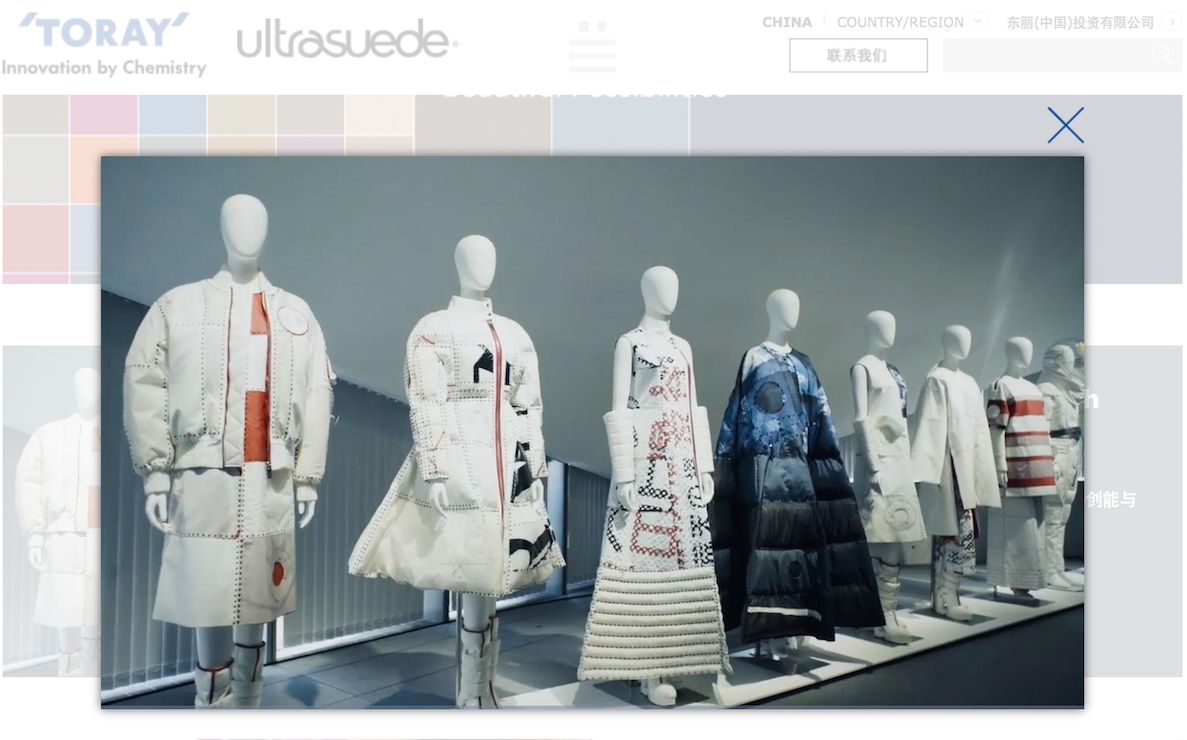

Toray is using fabric technology innovations one after another to subvert clothing production in Japan and around the world. In February this year, Toray teamed up with Japanese futurist designer Yuima Nakazato to hold the Yuima Nakazato Exhibition-Harmonize event at the design art gallery 21_21 Design Sight inside Roppongi Tokyo Midtown. During the period, the series of works released by Nakazato Weima’s personal brand at Paris Haute Couture Week and the production process of the series were exhibited.

(Note: The directors hired by 21_21DesignSight Design Museum all have well-established backgrounds, including well-known fashion design master Issey Miyake, graphic designer Taku Sato, and product designer Naoto Fukasawa. These three designers plus advertising director Noriko Kawakami , jointly responsible for the project curation of the museum)

In order to realize mass customization of clothing, Zhongli Weima created a unique clothing-making method: using laser cutting, plotting machines and other equipment to cut the fabric into square parts of several centimeters, and then re-piece them together. Among the works released during Paris Haute Couture Week, Yuima Nakazato used Toray’s ultrafine fiber artificial suede Ultrasued in her works. This fabric has many advantages such as high breathability, permeability, and easy care and maintenance.

Toray is aiming to build a stronger clothing production organization, integrate technology, and improve production efficiency. In the 2017/2018 fiscal year ending in March 2018, Toray’s fiber division sales increased by 6.7% year-on-year to 913.6 billion yen, and operating profit increased by 8.5% year-on-year to 72.4 billion yen. The products of Toray’s fiber division include: non-woven fabrics required for air bags, diapers, car seats, etc., and clothing fabrics. In 2017, Toray acquired nearly 30% of the outstanding shares of Hong Kong Pacific Textiles for 60 billion yen to strengthen the research and development of new knitted raw materials.

The supply of apparel fabrics is one of the development focuses of Toray’s fiber department. In the fiscal year ending in March 2017, Toray’s fiber department had sales of 850 billion yen, of which the apparel fabric transaction amount was approximately 270 billion yen, approximately Accounting for 30% of the total. The apparel fabrics department currently mainly cooperates with Uniqlo. According to the cooperation agreement, the two parties hope that the transaction amount will reach 1 trillion yen (approximately RMB 59 billion) in the five years from 2016 to 2020.

Mitsuo Oya, head of Toray’s fiber department, said: “Long ago, the Hong Kong subsidiary’s own factory began to study issues such as automated production and how to improve production efficiency. By introducing the most advanced production equipment, we have achieved the goal of one person Operate several machines. Including cooperative factories, we can know in real time how many pieces of which model are produced in which place according to SKU.” (Title: Japan’s Toray launches cutting-edge clothing R&D laboratory TECHNORAMA III)

AAA

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA