Nanomembrane composite fabrics and nanofiber composite fabrics help intelligent composting and fermentation technology systems

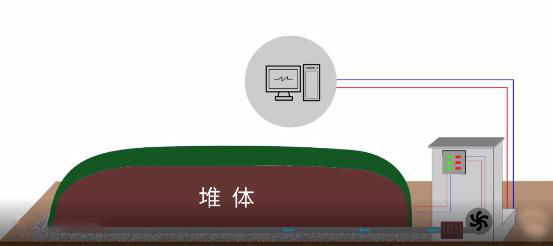

The nanomembrane intelligent composting fermentation technology system can provide corresponding solutions based on the total amount of manure in the project county, planning manure treatment centers, decentralized layout, centralized processing, shared utilization, reducing transportation costs, and solving environmental odor problems.

Chinese name: Nanomembrane intelligent composting technology

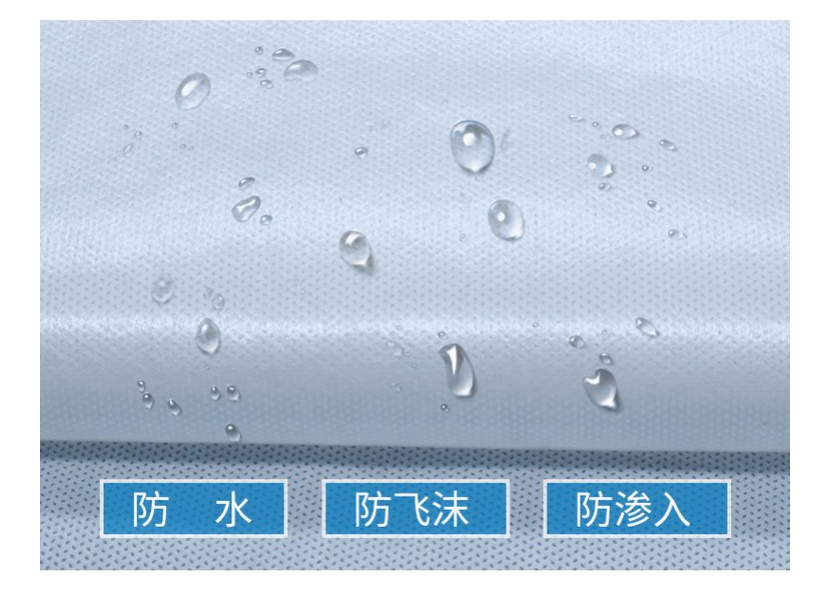

Features: waterproof, little impact on surrounding environment, no odor spillage, etc.

Material: nanomembrane composite fabric

Organic compost fermentation technology system

Technical features

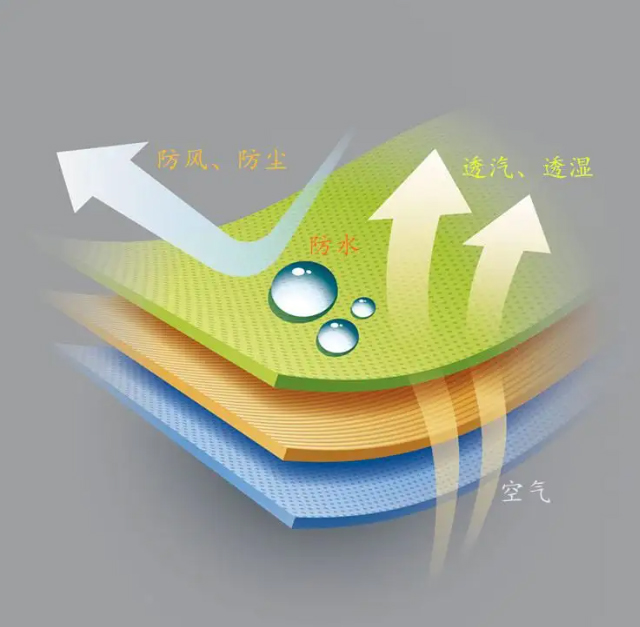

Nanomembrane smart composting does not require the construction of a factory building or a shed, but only needs to harden the site. It is compatible with the current mainstream trough-type and stack-type composting existing infrastructure. The service life of the equipment is as long as 8-10 years; it is environmentally friendly and odorless. Nanomembrane is a polymer selective breathable membrane with functions such as waterproofing, moisture permeability, sterilization, and deodorization. It has little impact on the surrounding environment, has no odor overflow, and does not need to be equipped with odor collection and treatment equipment. It has a wide range of adaptability.

Nanofilm composting There are two main traditional methods of composting:

Anaerobic composting:

The composting process mainly uses anaerobic microorganisms under anoxic or anaerobic conditions. In addition to humic organic matter, carbon dioxide and methane, the final products also include reducing substances such as ammonia, hydrogen sulfide and other organic acids. The process is simple and does not require ventilation, but the reaction rate is slow and the composting cycle is long.

Organic compost fermentation technology system

Aerobic compost:

Under artificial control and a certain carbon to nitrogen ratio (C/N), moisture, temperature and ventilation, the process of converting organic matter into stable humus through microorganisms. The finished product after fermentation of this type of compost is odorless and fly-free, but has a faint earthy smell.

As a new composting method, nanofilm composting has appeared in the eyes of the majority of users. This method combines the advantages of the above three composting methods and reduces their disadvantages, bringing a new choice of compost fermentation to the majority of users.

Since nanomembrane compost uses new membrane materials for cover fermentation, it can be fermented in the open air, and the membrane material has unidirectional permeability, which can effectively isolate odor and external water molecules, but internal water vapor can pass through normally, which is better. Ensure the internal fermentation state. Moreover, the NCS intelligent molecular membrane composting fermentation system under China Shipping Environment can customize special membrane materials according to the climate of different regions, so that fermentation materials in different climates and humidity can obtain a good fermentation environment under the cover of membrane materials.

Since nanomembrane compost fermentation only requires an air supply system, a membrane-covered fermentation system, and an intelligent control system for fermentation, the investment cost is only 30% of that of other reactor fermentations, which greatly reduces the investment cost and has low operating costs. Compared with traditional operating costs, nanomembrane fermentation has reduced operating costs by 90%, and has completely realized the unattended function, allowing you to control the fermentation situation without leaving home.

R&D focus

The development and testing of front-end and back-end auxiliary equipment for nanomembrane intelligent composting, and optimization focus on establishing a system solution with nanomembrane as the core process.

Market application

Nanomembrane smart composting technology has achieved certain results in its market promotion at this stage, and more than 30 demonstration bases have been established in Shandong, Hebei, Jiangsu, Inner Mongolia, Hubei and other places.

The smart nanomembrane composting technology has added an Internet of Things system. The park can download an APP to monitor the humidity, temperature and oxygen content in the smart nanomembrane in real time, and regulate it based on the data.

Reading Tips: Pollution from livestock and poultry breeding is a focus of current social concern. The state encourages the selection of economically applicable treatment models based on the resources and environmental characteristics of different regions. For farms with different breeding species and different breeding scales, how to choose an appropriate livestock and poultry manure treatment mode is still a difficult problem faced by many farms. In response to this issue, the reporter interviewed Ma Ruiqiang, a PhD in microbiology from China Agricultural University, a senior agronomist, a postdoctoral fellow at the Institute of Agricultural Environment and Sustainable Development of the Chinese Academy of Agricultural Sciences, and the general manager of Zhongnong Chuangda (Beijing) Environmental Protection Technology Co., Ltd., to analyze various aspects for us. Treatment model of breeding livestock and poultry manure�>

148cm

Yarn count

40s

quality standards

line mark

style

modern

Custom processing

no

Whether to import

no

Weight

300-500g/㎡

Packaging specifications

Whole roll packaging

Schematic diagram of organic compost fabric

1. Nano-membrane composite fabrics belong to the field of nanofiber membrane technology, and particularly involve a preparation process for nano-fiber membrane composite fabrics.

2. Nanofiber refers to a linear material with a certain aspect ratio that has a diameter of nanometer scale and a larger length. Through technologies such as electrospinning, nanofibers can be spun onto base fabrics such as non-woven fabrics to produce composite fabrics with different functions. Among them, nanofiber membranes with antibacterial properties can be electrospun to improve the antibacterial properties of composite fabrics.

3. However, in the existing technology, antibacterial substances such as silver nitrate are generally added to the spinning liquid to improve the antibacterial performance of composite fabrics, which has certain toxic and side effects; in addition, although there are also methods of adding traditional Chinese medicine extracts to the spinning liquid and other natural antibacterial substances to improve the antibacterial performance of composite fabrics, but there are problems such as relatively average antibacterial effects.

In order to develop waterproof and breathable fabrics with high waterproofness, good moisture permeability and excellent mechanical properties, polyvinyl butyral (PVB) adhesive was introduced into the polyurethane-based spinning solution, combined with electrospinning technology and thermal Polyurethane-based nanofiber composite fabrics are prepared by pressing process.

The structural morphology of thermoplastic polyurethane (TPU) nanofiber membrane and polyurethane (PU)/fluorine-containing polyurethane (FPU)/PVB nanofiber membrane and the performance of the fabric after hot pressing composite with base fabric (polyester cloth) were studied. The results show that when the mass fraction of TPU is 22% and the mass fraction of polyurethane-based spinning solution is 14.5%, the point-like structure formed can not only effectively bond the fiber membrane and the base fabric, but also ensure the breathability of the composite fabric;

Nanomembrane fabric function

The polyurethane-based nanofiber composite fabric has a breaking strength of 89.6 MPa, a water pressure resistance of 51.6 kPa, a moisture permeability of 7.6 kg/(m^(2)·d), and an air permeability of 14.6 mm/s.

TPU/PTFE nanofiber membrane composite fabric has good windproof, waterproof, moisture permeable, antibacterial and other functions.

The excellent waterproof, moisture-permeable and antibacterial properties of nano-membrane composite fabrics can meet its diversified applications in outdoor sportswear, chemical protective clothing, compost fermentation and other fields.

Nano film composite fabric, nano film composite fabric, nano fiber composite fabric, nano film composite fabric

FabricBusiness technical support contact: Ms. Yang 139 1265 2341

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AAAclass=”MsoNormal” style=”text-align:center;”>

Nanomembrane fabric function

The polyurethane-based nanofiber composite fabric has a breaking strength of 89.6 MPa, a water pressure resistance of 51.6 kPa, a moisture permeability of 7.6 kg/(m^(2)·d), and an air permeability of 14.6 mm/s.

TPU/PTFE nanofiber membrane composite fabric has good windproof, waterproof, moisture permeable, antibacterial and other functions.

The excellent waterproof, moisture-permeable and antibacterial properties of nano-membrane composite fabrics can meet its diversified applications in outdoor sportswear, chemical protective clothing, compost fermentation and other fields.

Nano film composite fabric, nano film composite fabric, nano fiber composite fabric, nano film composite fabric

FabricBusiness technical support contact: Ms. Yang 139 1265 2341

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA